|

A seriously small

layout...

Perhaps the smallest layout in this Gallery, El Dorito

Mine was designed as an automated shelf toy, to delight children of all ages

who love to watch it work. It provides continuous action and an extremely simple

track plan! Perhaps the smallest layout in this Gallery, El Dorito

Mine was designed as an automated shelf toy, to delight children of all ages

who love to watch it work. It provides continuous action and an extremely simple

track plan!

Rolling stock is just one bottom-dumping wagon and a very small "critter"

(llike a Simplex or a home-made battery loco). The car fills up inside the mine building,

from a hidden bunker that loads at the rear roofline.

Then, under automatic shuttle control, the "train" carries its load of

mine tailings (unwanted excavated earth and rock) out to the end of the trestle.

There, it automatiically dumps its load into the lower bunker. Then the train runs

back into the mine building and begins the cycle again. The operator occasionally

refills the upper bunker from the lower one.

This operation is completely prototypical -- hauling excavation rock and dirt from

the mine to a nearby tailings pile. To add animation to this little layout, try automating

the elevator lift wheel atop the mine building ... it turns in one direction to send

the elevator down into the mine, then reverses to bring a load of tailings to the

surface. Add a flashing red light when the elevator arrives -- and maybe a loud klaxon

to emphasize the point.

Action in this mine is continuous!

|

|

At Last... a G-scale Micro!

Chris Gilbert has done it again! This time,

he's designed a working G-scale line ... in a micro layout size of four square feet!

Stourbridge Town is a working layout, accurately reflecting its prototype,

in a space of only 72x8 inches! Chris Gilbert has done it again! This time,

he's designed a working G-scale line ... in a micro layout size of four square feet!

Stourbridge Town is a working layout, accurately reflecting its prototype,

in a space of only 72x8 inches!

The prototype, Chris's "local" branch line, shuttles from Stourbridge Town

down to Stourbridge Junction -- under a mile away -- up to 60 times a day, every

10 minutes or so. Chris has chosen to use a North American Budd RDC car -- measuring

nearly three feet in G -- as his rolling stock.

The layout, shown above, models the Stourbridge Town platform (photo at right), from

which the RDC disappears under an overbridge. Under automatic train control, it pauses

for a time in the hidden half of the layout, then reemerges at the platform, where

it pulls in and pauses again. Then repeats.

Completely prototypical operation -- repeated as often as desired, in full G scale,

in the space of a long bookshelf ... what more could one ask?

The interesting looking vehicle at the Stourbridge Town platform in the photo is

an experimental flywheel-driven light rail vehicle being developed by Parry People Movers Ltd. It runs on the branch on Sundays.

|

Take a Long Ride...

Recreating long-ago seaside holidays is

the magic of Walmington Pier, a British HO layout which exactly reproduces the push-pull

operation of a typical English seaside resort and pier in the Edwardian era, early

in the Twentieth Century. Dave Carson (pictured at right), from Chelmsford,

created the layout and has exhibited it widely in England. Recreating long-ago seaside holidays is

the magic of Walmington Pier, a British HO layout which exactly reproduces the push-pull

operation of a typical English seaside resort and pier in the Edwardian era, early

in the Twentieth Century. Dave Carson (pictured at right), from Chelmsford,

created the layout and has exhibited it widely in England.

The complex track plan is shown above. The tram car is an "Anglicised"

version of the Bachmann San Francisco cable car in HO scale. As reworked by Dave,

it's a close copy of a "winter car" used on the well-known pier at Southend-on-Sea,

which is the world's longest and busiest.

In his day job, Dave works at a considerably more complex bit of trackage -- he's

a manager for Metronet Rail SSL Ltd (formerly London Underground) based in the train

yard at the east end of the District Line. He comments, "We stable

29 trains every night on seven single-train-length shed roads and 13 double-train-length

yard roads, all fanning off three reception roads. This is my other layout, and it

occupies 48 acres!"

UPDATE (25 August 2004)

Dave was recently promoted away from Upminster Depot

to become a Supplier Auditor based at HQ in Holborn but travelling around the UK

inspecting train equipment suppliers' quality systems.

For more information about the fascinating pier railways of England, I can heartily

recommend the Oakwood Press book, Pier Railways & Tramways of the British

Isles, by Keith Turner, ISBN 0-85361-541-1. For more information about Dave Carson's

enchanting model pier, see Model Trains International magazine, issues #34. 36 and 42. Photos are by Greg Dodsworth.

|

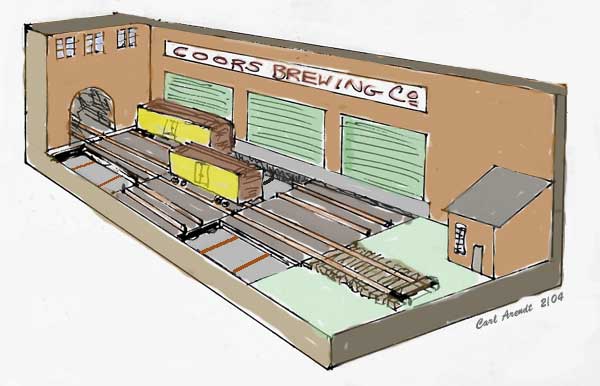

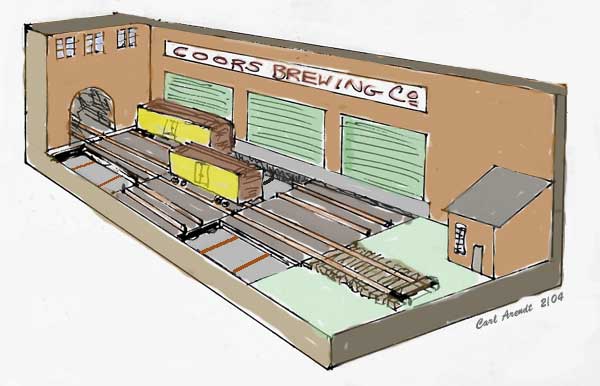

How They Load Beer

at Coors

Mike McLaughlin, from Denver, Colorado, recently

sent me a very unusual layout idea. Mike wrote:

"I worked in the transportation department at Coors Brewing Co. in the early

70s and they had (still have) a unique system for loading box cars with beer. A railroad

track served 7 loading doors on one side of the warehouse and 6 doors on the other.

A set of two transfer tables served each door so that individual cars could be spotted

and pulled as required.

"The 'inside' table would hold a 60' RBL car next to the loading door, and upon

completion of loading, the table would be run out from the door to push out the 'outside'

table that was aligned with the switching lead and align itself with the lead, allowing

the load to be pulled by a switch crew. An empty was then spotted on the 'inside'

table, which was returned to the door, pulling the “outside” table back into alignment

with the lead."

To clarify the operation, Mike drew up a micro-sized version of this lashup, called

A Pony Keg of Coors.

Selective compression has reduced the number of

loading doors to three. The switching track enters from a hidden cassette at the

left, passes the three loading doors on the "outside" transfer tables,

and culminates at the end of the one-car "tail track". Operation closely

matches the prototype.

Mike again: "The catch is that not all cars were loaded at the same rate. Most

product was loaded directly off the production lines, but some product was only run

say one or two shifts per day (quarts, 8 oz, etc.) while kegs came from a different

part of the brewery. A 'mixed' car might be loaded in 3 hours, while a 'straight'

car of 12oz cans would take less than an hour (7200 cases per car -- at a six-pack

per day, it'd take you almost 79 years to drink it all!) Thus the crews had

to very carefully plan their spotting sequence so that they didn't have to run to

the yard to get rid of their loads before all their empties had been spotted."

Believe it or not, Mike designed a very ingenious scheme of rods, slots, and catches,

which would allow the layout operator to run each door from a single pull-rod and

work very much like the prototype tables. The scheme is too complicated to illustrate

here -- if you're seriously interested, and I'll email back Mike's description and diagrams.

Why "A Pony Keg of Coors?" Because the layout is designed to be 9"

high, and the volume of the pike -- 7"x27"x9" -- is almost the same

as the volume of a pony (half) keg of beer -- 7.875 gallons! Needless to say, it

weighs considerably less.

Well, as you might expect, I couldn't resist this

one! I immediately set pencil to paper and designed a larger version for O-scale

operation using 40-foot reefers and a small switch engine, like a four-wheeled diesel

or a 44-tonner. And for simplicity, I reduced the transfer-table count to one per

door with two tracks on the table. Here's the result, A Keg of Coors.

Operation is much the same as above, with each traverser

being pushed and pulled by rods fed through the layout side, either at the front

or the rear. Trains enter beneath an office wing which conceals a cassette that holds

the switch run's consist. Again, the challenge is that not all doors will be ready

for switching at the same time. A form of random choice (such as pulling cards from

a hat) can determine the sequence of loading and spotting of empties, and the crew

will have its hands full on every trip from the yard to the brewery!

Unlike most micro layouts, this one might be a good bet for timetable operation.

With a fast clock (running, say, five minutes to the hour) a random drawing could

determine the time when each car would be loaded and pushed out to the switching

track. The railroad crew would really have to be alert to make sure it didn't get

trapped or bottlenecked.

The layout might look something like this:

Needless to say, the name comes from the fact that

this layout, at 51"x9"x10" comes very close to the volume of a keg

of beer -- 15.75 gallons. Thus: A Keg of Coors. Skoal! And many thanks to

Mike McLaughlin, who put considerable time and effort into figuring out ways to duplicate

the unique Coors loading system in model form (and taught me how to measure layout

volumes in kegs and barrels)!

|

A Tramway to Cuddle!

Let me hasten to add, "Cuddle" is the

name of a place on the South Coast of England where shale is quarried and processed

to extract the shale oil, which is put up in barrels and shipped to markets around

the world. This activity has been going on for some 400 years at Cuddle.

Andy Anderson, who lives in Southampton, has taken that simple outline, imagined

a tramway to serve the industrial process, and then created what is to me a brand

new operating idea: switching "loads" instead of "wagons" or

"cars"! For details, you really need to consult Andy's website,

but here is his sketch of the resulting layout plan.

Cuddle Shale-Oil Wharf is 36 inches long

(90 cm). It's a completely straight piece of track, without turnouts. By cunningly

"folding" the process back on itself, Andy has managed to model the entire

procedure of extracting and shipping shale oil, and placed it on this single wharf

scene.

At the center of the pier and its activity is the Retort House, based on an actual

structure featuring a modelgenic clock tower, where the shale is "cracked"

in retorts fueled by coke. The resulting barrels of oil are hauled by rail to the

boats for shipment. The waste product, spent shale, is discarded and taken by rail

to the spoils tip for dumping. All of this loading and hauing is performed by the

Gn15 tramway, which also has an Engine House at the end of the pier to store its

small but strong diesel locomotive.

Here's Andy's description of the switching game that results from modeling this industrial

process, switching and transporting flatcar loads (referred to as tubs):

"Coke and shale are loaded into tubs offstage (at left, behind a rise in the

landscape) and placed on the flats. These are taken to the retort house and loaded

into the appropriate places. Waste is discharged from the retort house into empty

tubs to be taken to the tailings (waste shale tip) whilst product, in small barrels,

is loaded onto flats to be taken to the boat.

"The 'puzzle' comes as follows: The 'coke/waste' tubs are loose filled, whereas

the 'shale' tubs are permanently loaded and disappear into the retort (to be carried

behind the scenes back to the loading area). On average, an operator picking up two

flats in the loading area will receive one tub of each type, but sometimes will get

two of one or two of the other. The retort house takes equal quantities and disgorges

one waste and one product in return.

"Shale tubs disappear into the retort house leaving an empty flat for carrying

barrels. Coke tubs are emptied but remain on the flat and can be refilled with waste

for disposal. The operator can return one, two or zero empty tubs in return for a

new load. Everything should be balanced, and there is space opposite the retort-house

for storing the spare tubs (probably four).

"The degree of difficulty can be controlled by:

- allowing a margin for error on the 50:50 loading

of the retort house, permitting an operator to get one or two tubs of either type

in excess of the other;

- reducing the amount of storage space opposite the

retort-house, blocking one or more bays with 'carelessly' placed piles of rubbish;

or

- blocking the last five feet of line so that only

the flat car nearest the loco can be used for product/waste runs.

'"The game ends when the operator is expected

to make a waste run and has no empty tub available, or when the operator runs out

of storage space and either is outside the acceptable 'mix' in the retort house or

is expected to make a 'product' run next."

Andy has an engineering bent and plans to use a computer program to create random

scheduling of the loads and productions, but these could be drawn from a hat, selected

by using a spinner, or chosen by rolling dice or drawiing from a shuffled deck of

cards.

I think Andy Anderson is onto something here, and I'm sure many industrial processes

could be simulated or modeled using similar approaches. If the idea appeals to you

and you work out your own version of this theme please let me know, and we'll add

it to the Micro Layout Design Gallery collection.

|

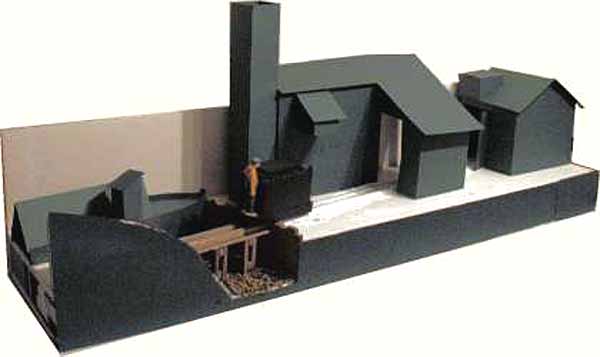

After much travail (on other projects), Andy

Anderson has created a mockup of Cuddle Shale-Oil Wharf using wood strips

and card. An overview of the mockup in action is shown above. As usually happens,

he has learned a lot from making this full-sized version -- and has made several

changes in his original design as a result.

After much travail (on other projects), Andy

Anderson has created a mockup of Cuddle Shale-Oil Wharf using wood strips

and card. An overview of the mockup in action is shown above. As usually happens,

he has learned a lot from making this full-sized version -- and has made several

changes in his original design as a result. Perhaps the smallest layout in this Gallery, El Dorito

Mine was designed as an automated shelf toy, to delight children of all ages

who love to watch it work. It provides continuous action and an extremely simple

track plan!

Perhaps the smallest layout in this Gallery, El Dorito

Mine was designed as an automated shelf toy, to delight children of all ages

who love to watch it work. It provides continuous action and an extremely simple

track plan!

Chris Gilbert has done it again! This time,

he's designed a working G-scale line ... in a micro layout size of four square feet!

Stourbridge Town is a working layout, accurately reflecting its prototype,

in a space of only 72x8 inches!

Chris Gilbert has done it again! This time,

he's designed a working G-scale line ... in a micro layout size of four square feet!

Stourbridge Town is a working layout, accurately reflecting its prototype,

in a space of only 72x8 inches!

Recreating long-ago seaside holidays is

the magic of Walmington Pier, a British HO layout which exactly reproduces the push-pull

operation of a typical English seaside resort and pier in the Edwardian era, early

in the Twentieth Century. Dave Carson (pictured at right), from Chelmsford,

created the layout and has exhibited it widely in England.

Recreating long-ago seaside holidays is

the magic of Walmington Pier, a British HO layout which exactly reproduces the push-pull

operation of a typical English seaside resort and pier in the Edwardian era, early

in the Twentieth Century. Dave Carson (pictured at right), from Chelmsford,

created the layout and has exhibited it widely in England.