|

|

||||||||

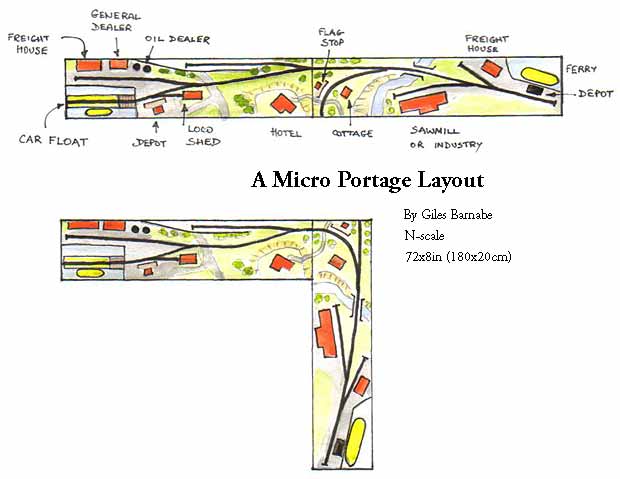

Conventional wisdom has it that switching layouts, especially those arranged in a straight line as on a shelf, MUST have a runaround loop (passing siding) in order to serve spurs facing in both directions. Here are a few examples of layouts without runaround facilities. They're interesting, ingenious, and sometimes inspiring. Take a look! |

||||||||

|

AT LAST ... A PASSENGER INGLENOOK!

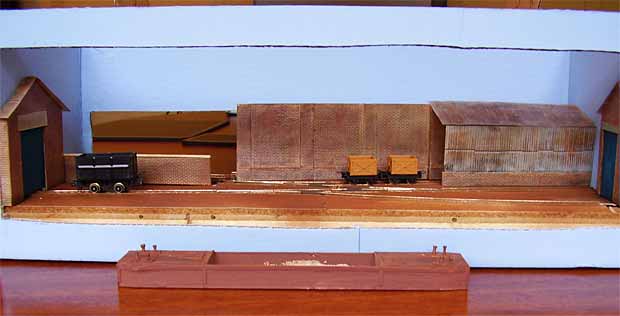

Working within the

constraints of a micro layout format, David designed a folding

baseboard that, folded, measures 52x10in and unfolded, 104x5in.

The 104 inches of length allows a full 5-3-3 Inglenook pattern with a long siding that holds five

full-length passenger carriages (coaches)! David mocked up the design (see photos)

using a Peco medium radius turnout on the "main line" and an unusual

long-radius one to the short sidings. Long passenger coaches look much

better on long, gentle curves, and this turnout combination works on a

micro layout without a space penalty! David had this to say about the important points of the design:One way to avoid runarounds on your shelf is to arrange the sidings to face in just one direction. This is the strategy of the classic Inglenook switching game (described in our Micro Layout Design Gallery). Now David Thomas, from Greenford, Middlesex England, has designed a micro Inglenook -- under four square feet in area -- that can handle five-car express passenger trains!

"1. You can have the fun of shunting a longish passenger train in a micro layout space. "2. If you're dealing with long passenger stock then medium and long points won't look silly, short ones probably will. "3. Making up trains with the stock in exactly the right order may be more prototypical for passenger operations than for freight trains. The restaurant has to be between the first and second class sections; coaches bound for the same ultimate destination must be marsalled together; you can't put the baggage cars in the middle of the train; the postal car has to be at the front; and train make up might well change on different days according to loadings. "4. You are probably making up two trains, the ongoing express and the shorter train carrying through coaches up a branch. "5. Including the station platforms makes it more exciting than just a set of carriage sidings. This model can easily be one end of a longer station -- you just don't see the other ten carriages. "6. In a city location retaining wall backdrops [represented in the mockup by backdrop boards] are entirely prototypical, and this folding arrangement creates an open box." You can add a lid to the box and easily have a self-contained travel bundle.   On

top of all that, David added a loco servicing spur to the design based

on his mockup -- still retaining an area of less than four square feet (below).

This spur provides a place to show off your best road locomotives

while the shunting is proceeding. One last word of advice from David:

if you decide to build this layout and can afford a bit more space,

leave wider margins at the edges of the table -- so if a train is

accidentally derailed, it won't plummet all the way to the floor!

|

||||||||

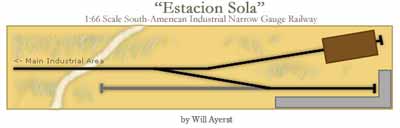

| A TRINITY OF FORKS Slightly simpler than the Inglenook is the plan that Chris Ellis, editor of Model Trains International magazine, has dubbed "The Fork". Although the switching is somewhat limited, well-planned scenery can make these little lines a pleasure to have around -- and they're portable enough to take to parties!  Estacion Sola is a Fork layout being constructed by Will Ayerst

from London, England. Though there's a kickback siding (shown in gray

on the plan), Will is modeling it as an abandoned spur, so the active

trackage is a true Fork pattern. Will comments, "I've decided to

go with 1:66 scale to get a 600mm (2ft) track gauge to model the loco

shed and worker drop off point of an industrial narrow gauge railway

somewhere in South America." Estacion Sola is a Fork layout being constructed by Will Ayerst

from London, England. Though there's a kickback siding (shown in gray

on the plan), Will is modeling it as an abandoned spur, so the active

trackage is a true Fork pattern. Will comments, "I've decided to

go with 1:66 scale to get a 600mm (2ft) track gauge to model the loco

shed and worker drop off point of an industrial narrow gauge railway

somewhere in South America." Construction

has just begun; trackage is Peco with some ties removed. We'll look

forward to receiving more progress reports from Will. By the way, he's

20 years old, and this is his first 9mm gauge railway. Construction

has just begun; trackage is Peco with some ties removed. We'll look

forward to receiving more progress reports from Will. By the way, he's

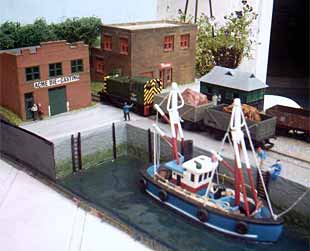

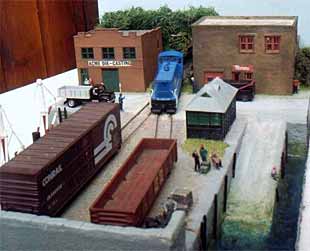

20 years old, and this is his first 9mm gauge railway. Port Abel is a very small OO scale layout built by Bob Hughes

from Cheshire, England. Measuring only 2x1ft (60x30cm) with a

24x6in (60x15cm) fiddle yard, the line represents, according to Bob, "a

rail served quay with a single track coming on stage between two

buildings and splitting into two spurs. The loco propels two or

three wagons onto the pier and swaps them for any wagons already there." Port Abel is a very small OO scale layout built by Bob Hughes

from Cheshire, England. Measuring only 2x1ft (60x30cm) with a

24x6in (60x15cm) fiddle yard, the line represents, according to Bob, "a

rail served quay with a single track coming on stage between two

buildings and splitting into two spurs. The loco propels two or

three wagons onto the pier and swaps them for any wagons already there."The layout, in common with Bob's Green End Quarry (pictured in Scrapbook issue No. 41) , is built from scrap wood picked up while he was driving a delivery van, and the name is "an awful pun."  As you can see from the aerial view, Port Abel is

a Fork design. Bob also designed it so it could be used with either

British or American rolling stock, as illustrated below. For more, see

Bob's website. As you can see from the aerial view, Port Abel is

a Fork design. Bob also designed it so it could be used with either

British or American rolling stock, as illustrated below. For more, see

Bob's website.

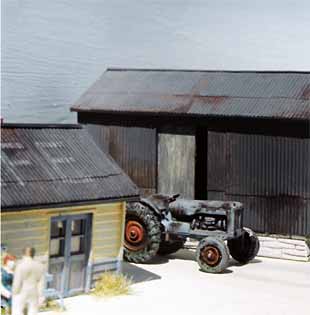

Sidetracks is a Z-scale Fork line that measures 60x7cm (24x2.75in). Alan Cox, from Swansea Wales, built the little layout while he was supposed to be writing his thesis, and thus the name! Sidetracks is a Z-scale Fork line that measures 60x7cm (24x2.75in). Alan Cox, from Swansea Wales, built the little layout while he was supposed to be writing his thesis, and thus the name! Using a wooden base from an old test track, Alan spread lightweight filler to make scenery and then laid the track back into the still wet filler on bendy plastic strip. After painting with homebase matte camouflage paint, the track was ballasted, rust painted on the rails and scatter material added. The signal is an old Märklin unit, manually controlled. As the second photograph shows, a railbus is used for motive power, and a tall embankment on the near side allows it to hide away between visits to the onstage scene. Alan really likes tiny layouts -- his next project is to model an underground (subway) station in a cardboard mailing tube! <g> |

||||||||

A TRIO OF KICKBACK SIDINGS  Shell Island is a minimum space EM gauge (4mm scale, 18.2mm gauge) layout built by Neil Rushby from York, England. It portrays the Cambrian Coast in British Rail days between the late sixties and early seventies. Shell Island is a minimum space EM gauge (4mm scale, 18.2mm gauge) layout built by Neil Rushby from York, England. It portrays the Cambrian Coast in British Rail days between the late sixties and early seventies.Neil has used skillful weathering and well-observed scenery to depict very convincingly a somewhat barren stretch of wind-swept coastline. The layout was featured in the August 2003 issue of Railway Modeller magazine. Neil's photos convey something of the feeling of the line, which measures just 30x15in (75x38cm), with a 24in three-road sector plate in the fiddle yard. For more information and photos, see Neil's website. From a layout design standpoint, adding the kickback siding to The Fork increases the switching complexity and requires careful planning of car (wagon) arrangements in the fiddle yard to enable the switching loco to serve all the sidings.    Location X was designed by Colin Peake,

from Nottinghamshire England, based around part of a narrow gauge

railway serving a Ministry of Defence establishment in the UK. The line

carries supplies and personnel around the military establishment.

Freight is delivered to the kickback siding, and passengers alight at

the station platform. Colin has suggested an unusual view block to help

conceal the "exchange siding" (fiddle area) from view -- a length of

standard gauge track with a line of rusting four-wheel vans typical of

MoD depots up to the present day. One scenic element that should add to

the visual appeal are the high-security fences separating different

areas of the site, giving a real air of security and perhaps mystery

as to the exact nature of the work going on here! Location X was designed by Colin Peake,

from Nottinghamshire England, based around part of a narrow gauge

railway serving a Ministry of Defence establishment in the UK. The line

carries supplies and personnel around the military establishment.

Freight is delivered to the kickback siding, and passengers alight at

the station platform. Colin has suggested an unusual view block to help

conceal the "exchange siding" (fiddle area) from view -- a length of

standard gauge track with a line of rusting four-wheel vans typical of

MoD depots up to the present day. One scenic element that should add to

the visual appeal are the high-security fences separating different

areas of the site, giving a real air of security and perhaps mystery

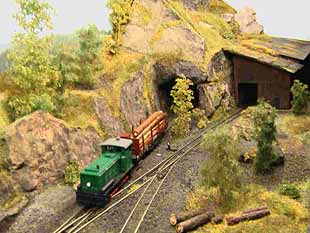

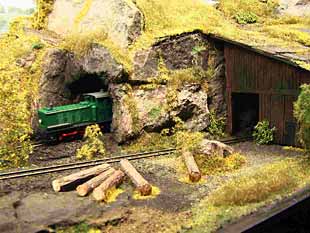

as to the exact nature of the work going on here!Peter Hoffmann,

who lives in Brunn am Gebirge near Vienna Austria, used the same track

plan but concealed the right rear spur to represent a tunneled route

up the mountain to the forest for timber. His HOe (1:87 scale on 9mm

track) logging railroad, Petey's Sawmill, measures

100x30cm (39x12in) and is fully automated. The following photographic

sequence traces the operating cycle and reveals some of the secret

mechanical magic performed inside the mountain.

s s   Our secret camera now reveals the machinations that are hidden inside the mountain! (Left) The loaded car arrives inside the mill, and the load is grabbed by a mechanical arm. (Center) The arm lifts the load clear of the log car. (Right) The arm moves the load over to the rear track., inside the tunnel entrance.

(Left above) The loco pulls the now-empty car out of the sawmill and forward to clear the switch. (Right) Reversing, it begins the long climb back up to the forest (by way of the tunnel).

(Above left) Still pushing the empty log car, the loco enters the tunnel, returning to the mountain forest. (Above right) But

what really happens is -- you guessed it -- the hidden mechanism

returns the log load to the car. Now everything is ready to repeat the

cycle, as many times as you wish! At intervals, the clever programming

diverts the loco and car to the extra spur at the front left, and the

train is parked for awhile to give the crew a beer break while the loco

is refueled.

|

||||||||

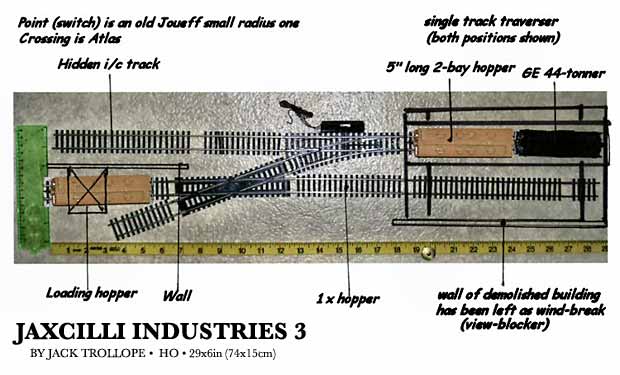

PERPETUALLY BUSY INDUSTRIAL RAILWAY Jack Trollope,

from the Highlands of Scotland, has designed yet another of his busy

industrial lines. Third in the series, this one is called Jaxcilli Industries 3.

Total rolling stock of the line comprises two 36-foot covered hoppers

(each about 5in. long) and a GE 44-ton switcher. Jack describes the

complex operation, worked out on a track plan of his own devising, this

way:

"Basically: 1. Car is pulled from hopper and dropped just in front of traverser, clear of the crossing. 2. Loco moves via traverser to top track and pulls inbound car from hidden i/c (interchange) track. 3. Turnout is thrown, and car is pushed onto crossing and dropped. 4. Loco reverses onto traverser (switch is thrown) and traverser moves to bottom track. 5. Loco picks up loaded hopper, pulls it onto traverser, traverser returns to top track. 6. Loco pushes car to hidden i/c and drops it. 7. Loco reverses to traverser, point is thrown and inbound car is picked up. 8. Traverser moves to bottom track, loco pushes empty car under hopper. 9. Loco returns to traverser." Got that? Needless to say, the loaded car -- now hidden away in the interchange (fiddle) track -- is unloaded by hand, while the empty car now spotted under the loader is being filled. Then the cycle repeats. This very tiny line provides a whole lot of continuing action in a very small space! |

||||||||

A NEW USE FOR YOUR EASTER EGG BOX  Inspired by the shoebox layouts featured elsewhere on this site, Anthony Bilton from Sheffield England, has devised a complex, very operational layout in a space of about 14x5in (36x12cm)! As Anthony tells it, "I got a chocolate egg for Easter, from my wife, that came in a box through the post. The egg was delicious, and the box seemed too good to throw away. The front opens up and over and the construction is strong and robust. As a result the layout will fit snugly in the box with cutaways at the front for viewing and rear for stock replacement and movement of the sector plate." Anthony's OO9/HOn30 mockup (above left) and his construction progress (right) with track in place and structures beginning to take shape show the layout's form and promising appearance. "But what," I asked Anthony, "about operations in this complicated knot of trackage?" Here's his reply, which delighted me: "The layout will represent the buildings end of a small limestone quarry/cement works. The very rear line and sector plate represent the rest of the network and are hidden from view by the large brick building and small retaining wall. Quarried items arrive in dumpers and are shunted into the covered track with the lean-to (right rear). These are exchanged for empties (through a hole in the backscene) and are then shunted away to reload. "Full flats of cement bags will be brought from offstage across the pointwork with two reversals and end up on the front right line being unloaded and stored in the shed at the extreme right. Full dumpers of quarried stone also arrive at the same siding after the two reversals to dump stone in the barge at the front. The quayside is yet to be modelled, but will be detachable and stored in the box. "Finally there is some coal traffic from the traverser to the front left siding and rail fed boilerhouse (large blue door at the left). This is occasional as the wagons will block the main siding entrance."  Sounds

to me like this will be a busy little railroad! We hope to keep you

posted on Anthony's progress. He's surprising himself with this layout!

His comment: "The exercise is proving to be very thought consuming to

ensure that maximum benefit is achieved from the limited space and that

everything goes together just right. As I haven't modelled for a good

20 years, the practicalities are quite complex at times!" Amen. But

worth the effort, I'd say!

|

||||||||

|

||||||||

| ||||||||